Process Elements: The Invisible Architecture of Distribution Operations

- Umashree

- May 5

- 6 min read

What is the first thing you notice when you walk into a distribution center? In my experience, most people immediately notice the physical elements—the inventory, the racking systems, the forklifts, the building itself. These tangible components seem to define the operation. But after two decades of working with distributors across the country, I've come to recognize that the true architecture of distribution excellence lies in something far less visible: process elements.

These invisible structures determine how efficiently materials flow, how accurately orders are filled, and ultimately, how profitably the operation runs. Yet they remain frustratingly difficult to identify, map, and improve—often existing only in the collective knowledge of your team rather than in documented systems.

Process Elements in Distribution Operations: The Hidden Framework

Think of process elements as the nervous system of your distribution operation. While physical elements form the body, processes are the neural pathways that enable coordinated movement. Without well-designed processes, even the most impressive physical infrastructure will underperform.

During a recent project with a mid-sized building materials distributor, we discovered that despite investing heavily in a state-of-the-art warehouse management system and new racking, their on-time delivery performance continued to suffer. It wasn't until we decomposed their processes to their fundamental elements that the real issues became clear.

The Five Fundamental Process Elements

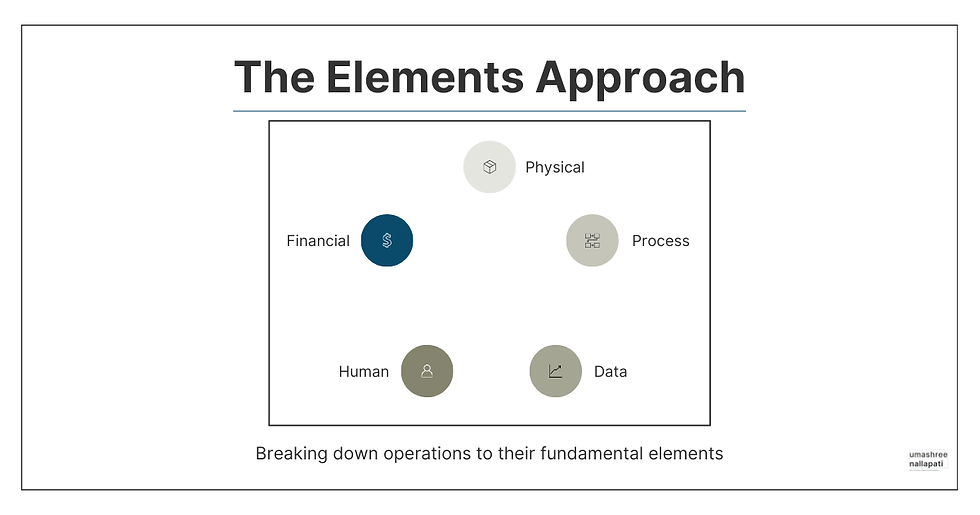

Through applying first principles thinking to dozens of distribution operations, I've identified five core process elements that exist in every operation, regardless of size or industry:

Workflows: The sequential steps that move products, information, or decisions through your operation

Decision Points: The critical junctures where choices are made that determine downstream outcomes

Handoffs: The moments when responsibility transfers between people, departments, or systems

Communication Channels: The pathways through which information flows

Exception Handling: The mechanisms for addressing deviations from standard processes

Each of these elements exists in your operation right now, whether you've designed them intentionally or not. And each represents both a potential point of failure and an opportunity for significant improvement.

Why Most Process Improvement Efforts Fail

Charlie Munger, the brilliant investor and mental models pioneer, often applies inversion thinking to complex problems. Following his approach, let's ask: Why do so many process improvement initiatives in distribution operations fail to deliver lasting results?

From my experience, the answer lies in addressing symptoms rather than fundamental process elements. Consider these common failure modes:

Attempting to optimize workflows without first making them visible

Overlooking critical decision points that create downstream variability

Focusing on individual department efficiency while ignoring handoff friction

Implementing new technology without mapping the underlying processes

Designing for optimal conditions rather than accounting for exceptions

The building materials distributor I mentioned earlier had fallen into several of these traps. They had implemented a new WMS without first mapping their order fulfillment process, creating a technological solution disconnected from operational reality.

Making the Invisible Visible: Element Identification

The first step in mastering process elements is simply making them visible. This requires a systematic approach to element identification and mapping.

Workflow Identification

Start by identifying the core workflows that define your operation. For most distributors, these include:

Order reception and processing

Picking and staging

Loading and shipping

Returns and exceptions

Inventory management

For each workflow, map the sequential steps from initiation to completion. The goal is not to document every minor detail but to identify the critical path that defines the process.

During a recent project with a plumbing distributor, we discovered that their order processing workflow contained 32 steps, but only 8 were truly value-adding. The remaining steps were legacy requirements from outdated systems or redundant checks that added time without improving accuracy.

Decision Point Analysis

Decision points are where the process can branch in multiple directions based on specific criteria. These junctures often create the greatest variability in your operation.

For each workflow, identify where decisions occur and document:

What criteria determine the decision

Who makes the decision

What information they require

How consistent the outcomes are

With the building materials distributor, we found that the decision point for allocating inventory to specific orders lacked clear criteria, resulting in frequent expediting and prioritization changes that cascaded through the entire operation.

Handoff Mapping

Handoffs—when responsibility transfers between individuals, departments, or systems— delays, errors, and miscommunications can occur.

Document each handoff in your core processes, noting:

Who/what is passing responsibility

Who/what is receiving responsibility

What information or materials are transferred

How the transfer is confirmed

The plumbing distributor discovered that the handoff between order entry and the warehouse involved an unnecessary batch process that created artificial delays. By redesigning this one handoff, they reduced order fulfillment time by nearly 40%.

From Analysis to Optimization: The First Principles Approach

Once you've identified and mapped your process elements, the optimization pathway becomes much clearer. Now you can apply first principles thinking to each element:

Question each element's purpose: Does this step, decision, or handoff truly add value?

Challenge complexity: Can we simplify this element without sacrificing effectiveness?

Examine variability: What causes inconsistent outcomes, and how can we reduce this variability?

Remove friction: Where do delays or errors typically occur, and how can we eliminate them?

Strengthen connections: How can we improve the flow between elements?

For the building materials distributor, this approach led to completely redesigning their order allocation decision point. Rather than relying on ad-hoc decisions by multiple team members, they implemented clear prioritization criteria and a visual management system that made the process both more consistent and more transparent.

Implementation: Bringing Process Elements to Life

Identifying and analyzing process elements is only valuable if it leads to implemented improvements. Based on my experience with dozens of distributors, I've found three key principles that drive successful implementation:

1. Visual Management

Process elements should be visible not just to management but to everyone involved. Visual management tools—from simple process maps posted in work areas to digital dashboards showing real-time workflow status—create a shared understanding of how work should flow.

The plumbing distributor implemented a simple visual order status board that dramatically improved transparency between departments and reduced the time spent on status inquiries by nearly 60%.

2. Decision Frameworks

Rather than relying on individual judgment for every decision, develop clear frameworks that guide consistent decision-making. These frameworks don't replace human judgment but rather structure it for better outcomes.

For inventory allocation decisions, the building materials distributor created a simple matrix balancing order age, customer priority, and delivery route efficiency. This framework reduced expediting by over 70% while improving on-time delivery performance.

3. Handoff Protocols

Formalize how responsibility transfers between individuals or departments. Clear handoff protocols ensure that nothing falls through the cracks and that each party understands their responsibilities.

By implementing a simple digital confirmation process for handoffs between order processing and the warehouse, the plumbing distributor virtually eliminated the "I thought you were handling that" syndrome that had plagued their operation.

Connecting Process Elements to Other Operational Elements

Process elements don't exist in isolation. They interconnect with the other fundamental elements of your operation:

Physical Elements: Processes must align with your physical infrastructure and equipment

Data Elements: Processes both generate and consume data

Human Elements: Processes are ultimately executed by people

Financial Elements: Processes drive financial outcomes through efficiency and effectiveness

The most successful distributors recognize these connections and design process elements that create harmony rather than friction between them.

Taking Action: Your Next Steps

If you're ready to start addressing the process elements in your operation, here are four concrete next steps:

Select a single, high-impact workflow to map and analyze. Order fulfillment is often an excellent starting point, as it touches most aspects of your operation.

Document the current state of this workflow, being brutally honest about how it actually functions (not how it's supposed to work in theory).

Identify the decision points and handoffs within this workflow, noting where variability or delays typically occur.

Apply the first principles questions to each element, challenging assumptions and identifying improvement opportunities.

Remember, the goal isn't to create a perfect process immediately. Instead, focus on making incremental improvements that move you closer to operational excellence.

Building Your Process Element Mastery

Understanding and optimizing process elements isn't a one-time project but an ongoing journey. As you develop this capability, you'll find that previously hidden operational challenges become visible and solvable.

The building materials distributor we worked with ultimately improved their on-time delivery performance from 83% to 97% while reducing expediting by over 70%—all without adding staff or significant technology investments. These gains came entirely from better understanding and designing their process elements.

By breaking down your operations to these fundamental process elements, you gain the ability to rebuild them with intention and purpose. And in today's competitive distribution landscape, that capability may be your most sustainable advantage.

Are you struggling with specific process challenges in your distribution operation? What workflow would you tackle first with this element-based approach? I'd love to hear about your experience in the comments below.

Want a step-by-step guide to mapping and optimizing your distribution processes? Drop a message using the contact form to get the Free Process Element Mapping Template.

Comments