Physical Elements of Distribution Operations: Identification and Analysis Framework

- Umashree

- Apr 14

- 6 min read

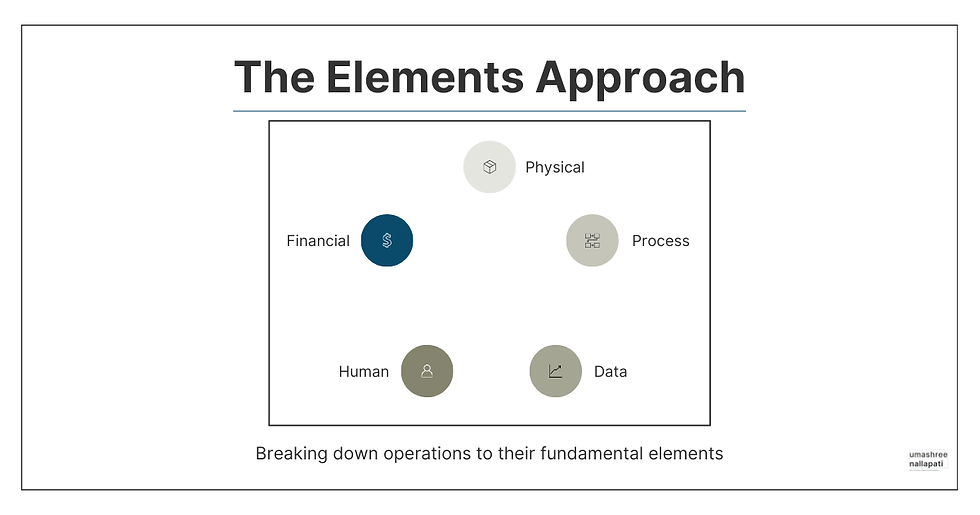

In my ten years of distribution operations experience, I've witnessed a consistent pattern: when operations struggle, leadership typically looks to process changes, software implementations, or personnel adjustments. Yet they often overlook the most tangible aspect of their operation – the physical elements.

These physical components form the foundation upon which all other operational elements rest. When we fail to properly identify, analyze, and optimize them, we build our operational systems on unstable ground.

Why Physical Elements in Distribution Operations Deserve Your Attention

Last month, I visited a building materials distributor struggling with persistent shipping delays. Their leadership had already:

Implemented new shipping procedures

Upgraded their warehouse management system

Retrained their staff

Hired additional personnel

Yet delays persisted. Within thirty minutes of walking their facility, the fundamental issue became clear – their physical staging area was insufficient for their current order volume. The best processes and people couldn't overcome this physical constraint.

This illustrates a principle I've observed repeatedly: Physical elements create the boundaries within which all other operational elements must function.

The Five Categories of Physical Elements

When analyzing distribution operations through a first principles lens, physical elements generally fall into these distinct categories:

1. Inventory Elements

These include not just the products themselves, but their physical characteristics that impact operations:

Dimensional properties: Size, weight, shape

Storage requirements: Temperature, humidity, security needs

Handling characteristics: Fragility, stackability, special equipment needs

Packaging configurations: Pallet patterns, case quantities, unit measurements

2. Facility Elements

The physical spaces where operations occur:

Layout design: Flow patterns, adjacencies, travel distances

Space allocations: Receiving, storage, picking, staging, shipping

Environmental factors: Lighting, temperature, noise, safety features

Structural constraints: Column spacing, clear heights, floor loads, dock positions

3. Equipment Elements

The tools and machinery supporting operations:

Material handling equipment: Forklifts, pallet jacks, conveyors

Storage systems: Racking, shelving, automated systems

Processing equipment: Packaging machinery, labeling systems

Measurement tools: Scales, dimensioning systems, counters

4. Material Flow Elements

The physical movement pathways:

Travel paths: Aisles, corridors, transitions between areas

Movement patterns: Routing logic, cross-traffic points, congestion areas

Transfer points: Loading/unloading zones, handoff positions

Bottleneck locations: Physical constraints limiting throughput

5. Interface Elements

The physical connection points between operational components:

Human-equipment interfaces: Controls, displays, operating positions

System transition points: Where physical goods enter/exit automated systems

External connection points: Shipping/receiving docks, customer pickup areas

Informational interfaces: Workstations, scanning positions, label placement

Figure 1: The Five Categories of Physical Elements in Distribution Operations. Each category represents a distinct set of tangible components that form the foundation of operational performance. Understanding these elements is the first step toward first principles operational excellence.

Physical Element Identification Framework

How do you systematically identify these elements in your operation? I've developed this framework that breaks the process into manageable steps:

Step 1: Physical Element Mapping

Begin by creating a comprehensive inventory of your operation's physical elements:

Conduct a physical walk-through with representatives from different functional areas

Document all physical elements observed, categorizing by the five types above

Photograph key elements for reference (particularly problem areas)

Record measurements of critical spaces and equipment

Note interaction points between physical and other elements (process, human, data)

Step 2: Element Purpose Identification

For each physical element identified, ask:

What is this element's fundamental purpose?

Why does it exist in its current form?

What operational outcomes does it enable or constrain?

What would happen if this element were removed or significantly altered?

This purpose identification often reveals legacy elements that once served important functions but no longer align with current operational needs.

Step 3: Constraint Analysis

Identify how each physical element may be limiting operational performance:

Capacity constraints: Maximum throughput limitations

Spatial constraints: Insufficient room for optimal processes

Configuration constraints: Suboptimal arrangements or designs

Compatibility constraints: Mismatches between interconnected elements

Condition constraints: Deterioration affecting functionality

Physical Element Analysis Framework

Once you've identified your physical elements, this analysis framework will help you evaluate their effectiveness:

Performance Assessment

For each critical physical element, evaluate:

Utilization rate: How fully is the element being used relative to capacity?

Cycle time impact: How does this element affect operational speed?

Quality contribution: How does this element influence error rates or damage?

Cost efficiency: What are the direct and indirect costs associated with this element?

Flexibility: How easily can this element adapt to changing requirements?

Relationship Mapping

Physical elements don't exist in isolation. Map their connections to:

Upstream and downstream elements affecting and affected by this element

Process dependencies that rely on this physical element

Data elements that monitor or control this physical element

Human elements that interact with this physical element

Financial elements impacted by this physical element's performance

Gap Analysis

Compare current state to optimal state:

Capacity gaps: Where demand exceeds physical capabilities

Design gaps: Where current configuration fails to support optimal flow

Technological gaps: Where outdated physical elements limit performance

Integration gaps: Where physical elements don't properly connect with other elements

Future-readiness gaps: Where physical elements will constrain projected growth

Figure 2: The Physical Element Analysis Framework guides you through a systematic process to identify, analyze, and optimize the physical components of your operation. This methodology has helped distribution centers achieve up to 40% performance improvements while reducing operational costs.

Implementation Example: Building Materials Distributor

Let me illustrate this framework in action with a company in the building materials industry:

Initial Situation

The distributor was experiencing:

Increasing error rates in order fulfillment

Rising labor costs despite stable order volume

Growing customer complaints about order accuracy

Physical Element Identification

Using the framework, I identified these critical physical elements:

Inventory Elements:

Large-format products (doors, moldings) stored without proper organization

Small items (hardware, fasteners) in mixed bins without clear separation

Facility Elements:

Picking areas arranged randomly rather than pick frequency

Insufficient staging space for assembled orders

Equipment Elements:

Outdated picking carts unable to accommodate both large and small items

Lack of mobile scanning equipment

Material Flow Elements:

Pickers crossing paths repeatedly, creating congestion

Orders following inefficient routes through the warehouse

Interface Elements:

Pick tickets printed in sequence unrelated to warehouse layout

No visual verification system for order accuracy

Analysis Findings

The relationship mapping revealed that:

The physical arrangement of inventory (by vendor) forced pickers to traverse the entire warehouse for most orders

The picking carts were incompatible with both the products and the order verification process

The staging area constraints caused rushed verification to free up space

Implemented Solutions

Based on the analysis, the distributor:

Reorganized inventory based on pick frequency and complementary products

Redesigned picking carts to accommodate mixed product types and scanning equipment

Expanded staging area by reconfiguring underutilized bulk storage

Implemented zone-based picking to reduce travel and congestion

Created verification stations with physical guides for accuracy checking

Results

Within 60 days, the operation saw:

42% reduction in picking travel distance

27% improvement in order accuracy

18% decrease in labor cost per order

Improved employee satisfaction due to reduced physical strain

Applying This Framework in Your Operation

You can implement this approach in your distribution operation through these steps:

Schedule a dedicated physical element mapping day with representatives from each operational area

Use the identification framework to document all physical elements, their purposes, and constraints

Apply the analysis framework to prioritize elements requiring attention

Develop an element optimization plan addressing the highest-impact opportunities first

Implement changes methodically, measuring results against baseline performance

Remember that physical elements often require more time and capital to change than process or data elements. This makes their proper identification and analysis even more critical – you want to get these foundational elements right.

When Physical Elements Aren't the Answer

While physical elements are fundamental, they're not always the primary issue. Consider these scenarios where other elements may be more important to address first:

When physical utilization is consistently below 70% (likely a process or human element issue)

When performance varies significantly between shifts using identical physical elements (likely a human element issue)

When data accuracy problems persist despite appropriate physical elements (likely a data or process element issue)

Conclusion: Building from Physical Foundations

First principles operational excellence begins with a clear understanding of your physical elements. As Charlie Munger would say, "To know the essence of something, take it apart and see how it works."

By systematically identifying and analyzing your physical elements, you create the foundational knowledge needed for truly effective operational design. Rather than building processes around flawed physical elements, you can reshape those elements to enable optimal operations.

In my next post, I'll explore how process elements interact with and build upon your physical foundation. Until then, I encourage you to walk your facility with fresh eyes, looking for physical elements that might be constraining your operational potential.

Does your operation have physical elements that constrain performance? I'd be interested to hear about your challenges in the comments below or via direct message.

Download the Physical Elements Assessment Worksheet

To help you apply this framework in your operation, I've created a comprehensive worksheet that walks you through the identification and analysis process step by step.

Click below to receive this subscriber-only resource.

Commenti